LIMITED TIME OFFER: TAKE $100 OFF PER CONTAINER (PURCHASE ONLY)!

The Interior & Exterior Dimensions of a Shipping Container

Understanding shipping container dimensions is a crucial part of the buying process. Let's select the best option for your needs.

Shipping Containers Dimensions & What You Need To Know

Understanding shipping container dimensions is a crucial part of buying the best container for your personal or business needs. In fact, numbers are key when it comes to containers, and if you want to store specific goods inside one, then you really need to understand measurements and measuring systems.

Before purchasing a storage container, we advise you to consider these factors:

- Eveon Containers only sells used wind & watertight 20ft, 40ft & 40ft HC Shipping Containers

- What the container will be used for (storage, shipping, building)

- Your budget

- What type of delivery will you require (pick up, flatbed or tiltbed delivery)

- Specific shipping container dimensions, including height & weight requirements

Working out the best possible size for your need vital to a seamless purchase. Be it a 20ft, 40ft, or high cube shipping container — we’ll guide you in your choice by explaining key ISO sizing differences below.

All Containers Below Meet ISO Standards

At Eveon Containers, all the containers we sell conform to universal ISO quality standards to ensure they are wind & watertight. These standards are minimum and maximum specifications when it comes to the measuring of containers for oceanic transport.

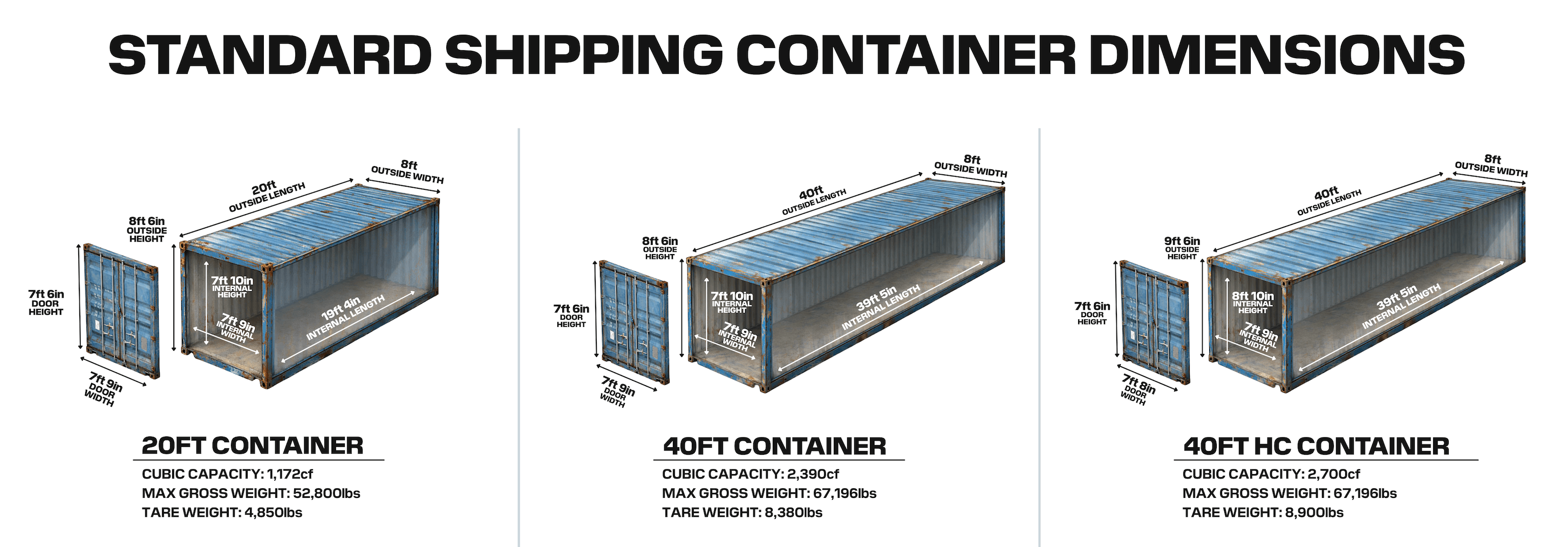

20ft Shipping Container Dimensions

Our smallest product offering is a 20ft container. Specs below:

- Exterior dimensions of this container are: 20’ (length) x 8' (width) x 8'6" (height).

- Interior dimensions are roughly: 19’4” (length) x 7’9” (width) x 7’10” (height).

- Have roughly 150sq ft of storage capacity.

- When it comes to width — standard shipping containers that meet ISO Certification will always measure 8ft wide externally and have an external height of 8’6’’. They also have a minimum width of 7.6ft and a minimum height of 7.6ft high.

40ft Shipping Container Dimensions

Should you need a somewhat larger container, then a 40ft container might very well be the best size for your requirements. These are the dimensions of a 40-foot container:

- Exterior dimensions of this container are: 40' (length) x 8' (width) x 8'6" (height).

- Interior dimensions are: 39' 5'' (length) x 7' 9'' (width) x 7'10" (height).

- Offer roughly 305sq ft of storage capacity

- Standard shipping containers that meet ISO Certification will measure 8ft wide externally and 8.5ft high. They will also measure roughly 7.6ft wide internally and have an internal height of 7.6ft.

40ft High Cube Shipping Container Dimensions

40ft HC Conex containers are our biggest product we offer. These containers are one foot higher than a standard 40ft container, allowing for goods with an increased height or the need for a forklift to transport goods in and out of the container. Check out the 40-foot container high cube dimensions.

- Exterior dimensions of a 40ft high cube shipping container are: 40' (length) x 8' (width) x 9'6" (height).

- Interior dimensions are: 39'5" (length) x 7'9" (width) x 8'10" (height).

- Offer roughly 320 sq ft of storage space

- Shipping containers that meet ISO Certification will measure 8.8ft high for the interior of high cube containers.

- High Cube (HC) shipping containers can be for both commercial and private usage. Since these Conex containers have a bit more space than standard ones, they are a ideal solution for housing bigger cargo or for an increased number of smaller items.

What To Expect From A Used Shipping Container

- Visible dents, scratches and rust acceptable

- No holes, or leaks

- Patches acceptable on walls and wooden floors

- Faded paint and paint patches acceptable

- Doors may be stiff to open & close

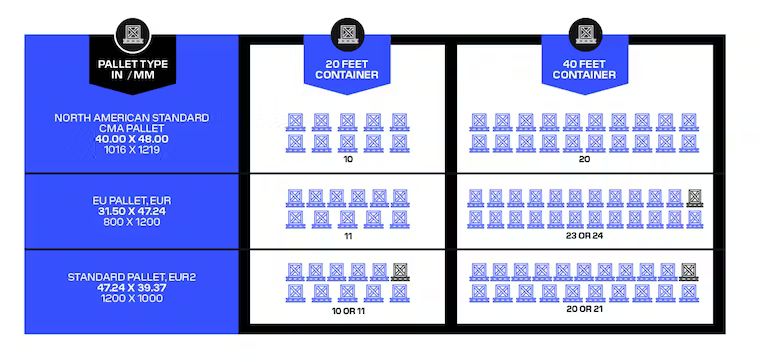

How many pallets fit in a container?

Many customers ask us how many pallets fit in a container. And our answer is always, well, that depends on the size of the pallet and the container itself.

A pallet is a wooden structure used in the transportation of goods. It has a particularly clever purpose in ensuring the stability of goods, especially those moved with a forklift or crane. Moreover, using a pallet ensures seamless storage and moving of goods due to the pallet’s universal size.

A commonly used pallet is the Euro pallet, which is 31.5” wide x 47.24” long. However, it’s important to note that pallets are also available with a dimension of 40” x 48”, the latter being more popular in North America. Additionally, another pallet available in 39.37” x 47.24” is commonly used in Asia and Europe, and this is considered similar to the North American version of the 40”x 48” pallet.

Given this information, a 20ft container can hold around 10 - 11 pallets (depending on the size and type of cargo stacked on the pallet). In contrast, a 40ft container can hold around 20 - 24 pallets (also, depending on the size and type of cargo).

Frequently Asked Questions

If you’re in the market for portable, modular storage and interested in purchasing a shipping container you have probably discovered the prices can be all over the place. Don’t be too alarmed. The cost of a shipping container can vary greatly depending on several factors, including its size, condition, location, and the market dynamics at play.

Much like the stock market, the price of a shipping container is influenced by supply and demand, weather conditions, global events, and geopolitical factors. Whether you're looking to buy or rent a shipping container, understanding the factors that affect the cost can help you make an informed decision.

Factors Affecting the Price of a Shipping Container

- Size and Type Shipping containers come in different sizes, with the most common being the 20-foot and 40-foot containers. Additionally, the type of container (standard, refrigerated, or open-top) will also influence the price. For example, a refrigerated container (also known as a "reefer") is often priced significantly higher than a standard container due to its cooling technology.

- Condition of the Container New or “one-trip” containers, which have only been used once, typically cost more than used containers. While used containers (also called “cargo-worthy” or “wind and water-tight”) are still in good condition and suitable for most purposes, they may show signs of wear and tear. However, used containers are generally more affordable than new ones, making them a popular choice for shipping, storage, or conversion projects.

- Location and Delivery Costs The location of the shipping container also plays a significant role in its price. Delivery charges to your location, especially if it's remote or requires special handling, can substantially increase the overall price of the container. Additionally, container prices can fluctuate based on regional demand, with prices being higher in areas with strong import/export industries. For example; cities closer to a large depot will have more supply than internal citiies where the nearest depot is 400 miles away.

- Supply and Demand The supply and demand dynamics in the shipping container market are highly volatile and can be influenced by a range of factors. Global shipping trends, such as changes in trade routes, surges in imports or exports, or natural disasters, can impact the availability of containers, causing price fluctuations. For example, during periods of high demand for shipping containers—such as the post-pandemic supply chain crisis—prices can skyrocket, making it more expensive to acquire a container.

- World Events and Geopolitical News Just like the financial markets, world events and geopolitical developments can affect shipping container prices. Political instability, labor strikes at key ports, or major shipping disruptions (such as the Suez Canal blockage) can cause delays in the shipping container supply chain, leading to price hikes. Additionally, fuel prices, which impact shipping and transportation, can also influence the cost of shipping containers.

Typical Shipping Container Costs On average, the cost of purchasing a new 20-foot shipping container can range from $3000 to $6,000, while a 40-foot container can cost between $4,500 and $8,000. For used containers, the price can be significantly lower, with 20ft used containers typically costing around $1,300 to $3,000, and 40ft used containers falling within the $1,500 to $4,500 range. Keep in mind that these prices vary based on location, market conditions, time of year and certifications.

Due ot the way the depots are laid out and safety and security you can not pick the color of your container. The carrier is instructed to pick quality over the color and the containers are stacked on top of each other in a manner that makes it impossible to sort once the delivery is in process.

Yes, shipping containers were engineered to be stacked.