LIMITED TIME OFFER: TAKE $100 OFF PER CONTAINER (PURCHASE ONLY)!

Prefab Shed vs. Corten Steel Shipping Container for Onsite Storage & Protection

Explore the differences in durability, cost, mobility, and customization to find the best storage solution for your home or business.

Have you run out of room at your home or business and need more space for your tools, equipment or personal belongings? Other than building your own shed which could cost thousands and take days, you have two options for purchasing read to go sheds.

A prefabricated (prefab) building and a shipping container from Eveon serve similar purposes but differ significantly in function and flexibility. A prefab building is typically lightweight, requires assembly on-site, and may not offer the same level of durability or long-term protection against harsh weather and theft.

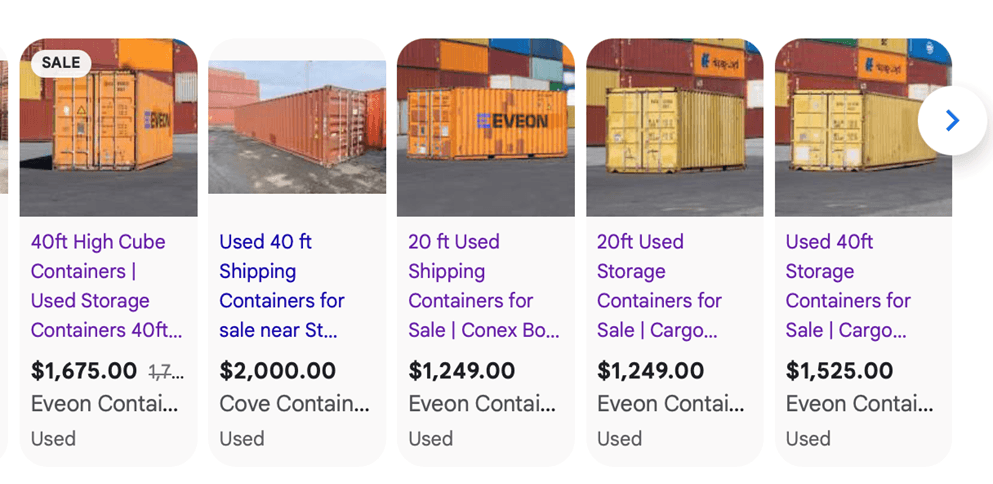

In contrast, a 20ft or 40ft shipping container from is made from heavy-duty steel, fully constructed, and ready to use immediately providing superior security, portability, and resistance to the elements. While prefab structures can be customized in design, an Eveon container delivers instant, reliable storage or workspace with the added benefit of being easily relocated whenever your needs change.

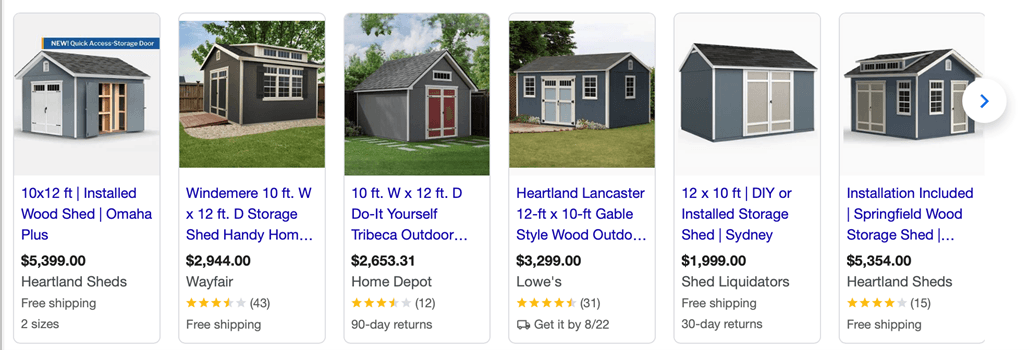

Prefab Plastic or Woodshed can run from $3K-$10K for a 10 x 12ft

Used Shipping Container (8ft x 20ft) that can run from $1100-$1600 depending on your location

The Pros & Cons of Choosing Shipping Containers vs. Prefab Structure for Onsite Protection

When it comes to protecting tools, equipment, or materials onsite, both shipping containers and prefab structures offer unique benefits. Understanding the pros and cons of each can help you choose the most practical and cost-effective solution for your project.

Eveon Shipping Container Benefits, Limitations, and Considerations

Pros:

- Durable & Secure: Made with heavy-duty steel and marine grade plywood floor to withstand heavy equipment, keep items weatherproof, and resist against theft or vandalism

- Cost-Effective: Usually cheaper upfront than prefab structures, especially used units

- Mobility: Easy to transport and relocate with a flatbed or crane

- Low Setup Time: Can be ordered, delivered & placed onsite in 3-5 business days

- Stackable: Stack containers vertically to save ground space

- Wind & Watertight Guarantee: Every container from Eveon comes with a WWT Guarantee

Cons:

- Cost to Customize: Modifying for doors, windows, ventilation, or insulation adds cost

- Temperature Control: Due to the WWT nature, insulation is required to regulate extreme heat or cold

- Aesthetics: Industrial look may not fit well in certain environments

- Space Constraints: Standard sizes (20ft or 40ft) may not fit irregular site requirements

Prefabricated Structures Advantages and Drawbacks

Pros:

- Customizable: Designed to specific size, layout, and use-case (offices, storage, workshops)

- Better Insulation: Prefab walls and roofs often can come with insulation built in

- Aesthetics: More professional look; can blend with site or corporate branding

- Comfort: Easier to add utilities (electricity, HVAC, plumbing)

- Lightweight Materials: Easier to modify, expand, or relocate without heavy equipment

Cons:

- Higher Initial Cost: Usually more expensive than a used shipping container

- Setup Time: Requires assembly, possibly foundations or anchors depending on size

- Security: Lighter construction makes it less secure against theft or extreme weather

- Durability: Not as rugged as steel containers in rough environments

- Mobility Limitations: Not as easy to pick up and move in one piece

Choose Wisely to Protect Your Investment in Onsite Storage

Whether you pick prefab or a used shipping container for your storage needs, we encourage you to do your due diligence to ensure you are not scammed or select an option that is not best for your home or business. It is advised you consult customer reviews and testimonials to make sure you are buying from a reliable partner.

Frequently Asked Questions

Container floors are typically constructed with marine-grade plywood, providing durability and moisture resistance. The floor features steel cross members, wooden floor joists, and treated plywood sheets.

A 20ft shipping container is 140.3 sq ft internal and 159 sq ft external. A 40ft standard or high cube shipping container is 304.6 sq ft internal and 320 sq ft external.

One great feature of shipping containers is that they can be stacked up to eight containers high, even when fully loaded. It is advised that containers of the same size are stacked since they will be more secure. There are companies out there that have equipment to handle stacking. Please consult an expert before attempting.